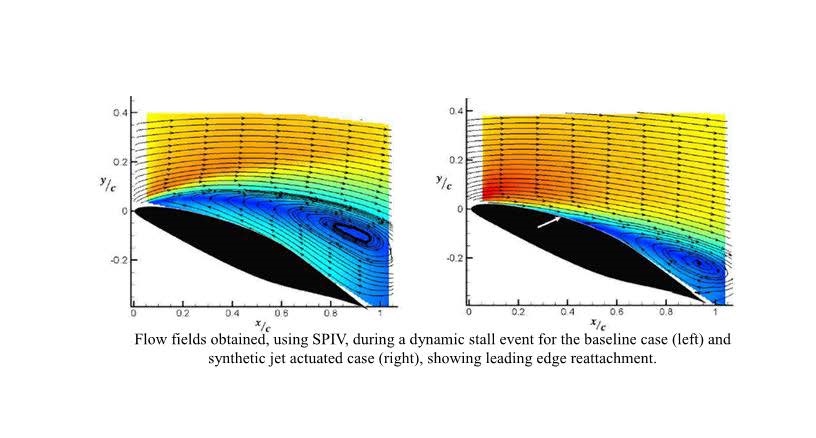

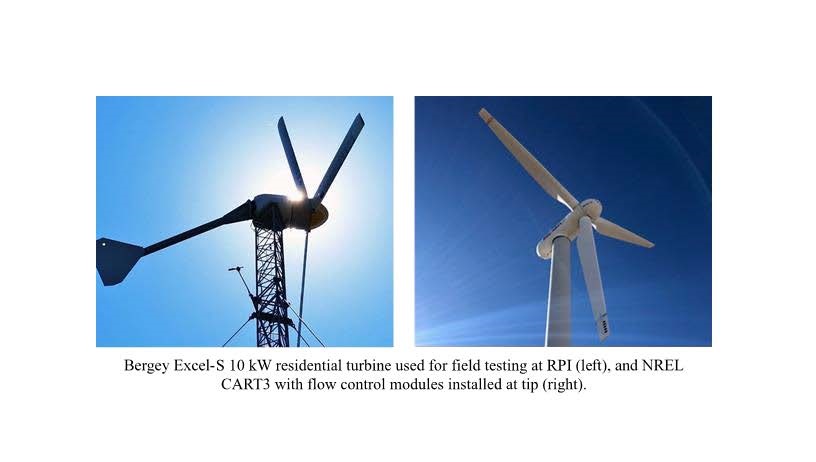

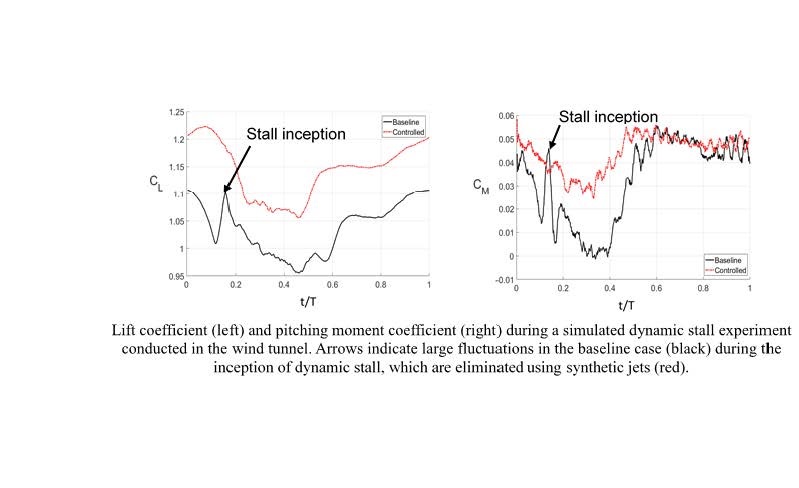

As wind turbines increase in size to capture more power, so do much of the adverse natural effects due to wind gusts, atmospheric turbulence, and yawed flow. Specifically, a large factor in wind turbine fatigue has been shown to be dynamic stall, a phenomenon where the angle of attack seen by the wind turbine blade pitches in and out of its stall angle, resulting in highly unsteady blade loading. To mitigate the structural stresses during dynamic stall, synthetic jets are installed near the leading edge of the blade to keep the flow attached through the dynamic pitching motion. For cases where deep dynamic stall is observed, we are researching smart ways of actuation to distribute the shedding of vorticity, associated with dynamic stall, in a more controlled manner. The project has two main thrusts: wind tunnel testing, to obtain optimal actuation techniques for dynamic stall, and field testing, of active flow control technology in real world conditions. Preliminary field testing at RPI has demonstrated the concept of installing synthetic jet actuators in a closed loop fashion on a wind turbine, and full-scale field testing at NREL has shown this application on both residential and utility scale turbines, which is the target market for these devices.

Related Publication:

- Rice, T., Taylor, K., Amitay, M., "Wind Tunnel and Field Test Results on Reducing Load Oscillations on Wind Turbine Blades using Synthetic Jets," 35th Wind Energy Symposium, AIAA Sci-Tech, Vol. 2017-1378, January 2017.