This thrust focuses on wing energy topics such as smart wind turbines and building integrated wind.

Smart wind turbine blades

As the desire to harvest energy from the wind increases, industrial manufacturers seek to implement techniques that improve wind turbine efficiency and longevity. The use of variable-speed rotors (used in most modern large-scale turbines) offers an efficiency increase by allowing the turbine to operate closer to its maximum aerodynamic performance at a wider range of wind speeds, thus extracting more energy from the wind. Typically, variable-speed wind turbines use aerodynamic controls in combination with power electronics to regulate the torque, rotor speed, and power. Aerodynamic control is normally achieved by active techniques such as variable pitch blades, or less commonly through trailing edge jets for circulation control and steady jets on the suction surface of the blade, or passive techniques such as gurney flaps, vortex generators, and compliant blades. Although these aerodynamic controls offer specific benefits, their implementation is limited for reasons of efficiency (in the case of active devices) or the fact that their effects are always present whether desired or not (passive devices).

Unlike the aerospace industry, where the interaction between fluids and structures is well-understood, the study of flow dynamics specific to wind turbines has only recently become a source of study. Efficiency improvements and structural load reductions are the motivations for these studies. A significant means of efficiency improvement (and subsequent reduction in energy cost) is the development of larger-scale turbines. In addition to the increased energy capture ability that larger turbines provide, their construction cost is proportionally lower when normalized to their increased energy production.

Larger turbines represent the future direction of the industry, but the design of larger systems is currently limited by structural and materials issues. Blade designs must be strengthened for the larger span, adding additional weight to the turbine. Vibration issues are increasingly problematic as turbine span increases, and conventional methods of controlling power and blade loads lose their effectiveness. The development of larger, more efficient turbines mandates a fundamental study of the interaction between the wind and the blade so that these effects can be considered and exploited in the design of larger turbines.

Motivation and Objectives

The literature concerning wind turbine efficiency improvements is extensive; both passive and active techniques have shown this capability. However, these techniques are either not very efficient (i.e., the power needed to implement the control is of the same magnitude as the effect) or are associated with penalties (e.g., passive tabs that are associated with additional drag when the control is not needed). The motivation of the research in CeFPaC is to improve wind turbine blade performance by efficiently controlling the blade’s aerodynamic characteristics. This is achieved by using synthetic-jet based flow control in a closed-loop system. Using this technology, the following objectives may be achieved:

- Increase the efficiency of the turbine by improving its energy capture capability at low wind speeds. This is accomplished by maintaining flow attachment over the blade at high angles of attack (preventing aerodynamic stall) thereby increasing the power coefficient at low speeds.

- Reduce loads at high wind speeds and during high turbulence or wind gusts. Gusts can result in a sudden increase in the effective angle of attack of the blade, which can yield high unsteady loads on the blade leading to structural failures. The synthetic jet flow control system is designed to work in conjunction with conventional pitch actuators to increase the system bandwidth. The distributed nature of the actuators has the ability to shed the excess lift from selected portions of the blade when wind shear exists across the blade.

- Reduce vibration of the turbine’s blades by actively controlling the flow over the blades. The reduction of vibrations is an enabling technology that promotes the development of longer blades needed to develop more efficient turbines.

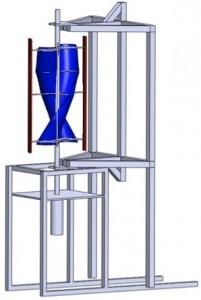

Building integrated wind (Smart buildings)

Airflow is as fundamental to human activity as water or light, yet it is an underutilized resource at the building scale due to its inherent inconsistency. Using an adaptive system, which is a hybrid of fluid and geometry based flow control strategies to control the airflow in and around buildings, will significantly improve the ability to:

1) Reduce wind loading by mitigating the vortex shedding on main wind force resisting systems and envelope systems in buildings and other structures.

2) Control heat transfer at the building envelope.

3) Control pressure differences at the building envelope.

4) Augment power output from building integrated wind turbines.

5) Manage indoor flows for improved indoor air quality and aerosol removal, and

6) Optimized HVAC performance.

Active Flow Control technology, already widely used in the aviation and auto industries, holds great potential for transfer to building scale. Synthetic jets are low energy, inexpensive, and mechanically simple devices, that introduce an opportunity for cost effective and energy efficient mitigation between climatic conditions and indoor mechanical systems at their natural intersection – the building envelope. The ultimate integration of these devices into systems outfitted with the appropriate sensors will enable their activation only as needed and ensure that building system performance is significantly improved while energy consumption is reduced. Active flow control that uses periodic excitation to exploit natural airflow instabilities has the potential to overcome the efficiency barrier.

Addressing the complexity of a fluid interface at the building envelope requires a consortium of architects, engineers, and industrial partners to viably demonstrate the performative aspects of this technology transfer from the aerospace industry. Climatic, environmental, and programmatic criteria are examined through parametric modeling, CFD simulations, and wind tunnel experiments to establish relations between active flow control and geometry-based flow management.