Completed Projects

Experimental investigation of the formation of secondary flow structures and interactions of a finite-span synthetic jet in a cross-flow at chord-based Reynolds numbers between 50,000 and 400,000 and angles of attack from 00 to 200.

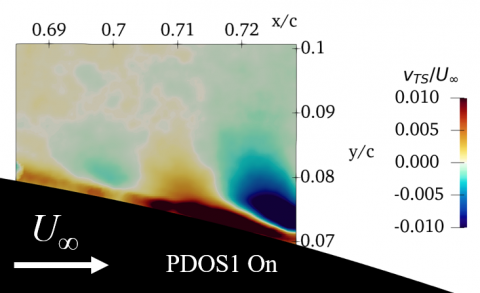

A turbulent boundary layer greatly increases the drag on a wing, and therefore aircraft fuel consumption. By delaying the transition of organized, laminar flow into disorganized, turbulent flow, billions a year can be saved in fuel costs. One way that this transition can be delayed is by using a vibrating surface element to suppress the Tollmien-Schlichting (TS) waves responsible.

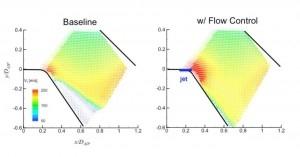

Attractive to aircraft designers are compact inlets, which implement curved flow paths to the compressor face. These curved flow paths could be employed for multiple reasons. One of which is to connect the air intake to the engine embedded in the aircraft body. Secondly, they allow for tightly packed, lightweight, and low volume propulsion system designs. Therefore, a compromise must be made between the compactness of the inlet and its aerodynamic performance. Currently, the length of the propulsion system is constraining the overall size of Unmanned Air Vehicles (UAVs). Thus, more efficient aircrafts could be realized if the propulsion system could be shortened. In order to suppress flow separation regions, passive or active flow control strategies can be employed.

A turbulent boundary layer greatly increases the drag on a wing, negatively impacting aircraft fuel economy. Unmanned aerial drones in particular experience transition to turbulent flow from the laminar regime at common flight conditions. Transition can be delayed in a number of ways including airfoil geometry and surface actuation to suppress the Tollmien-Schlichting (TS) waves responsible.

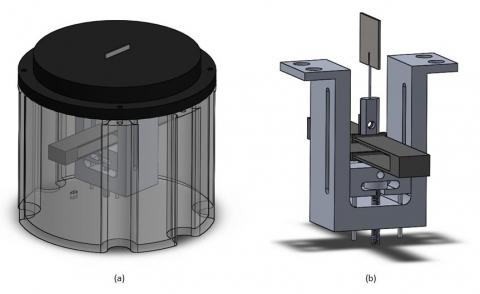

This project focuses on the development and application of piezoelectric linear actuators in different examples of active flow control. The primary goal of this research is to build and quantify custom piezoelectric bending beam actuators; the piezoceramic used is Lead Zirconate Titanate. Different actuators with varying parameters such as piezoelectric thickness and beam length are being fabricated and tested. These devices are actuated with a periodic function, resulting in an oscillating platform on which to mount different flow control devices.

Currently many vertical tails on commercial aircraft are oversized in order to compensate for an extremely rare and specific emergency scenario: A single engine out in high crosswind during takeoff and landing. Our goal is to improve the performance of a smaller vertical tail, which would allow for higher deflection angles, and therefore higher sideforce, in order to compensate for the high yaw produced during these emergency scenarios. This would allow for a significant decrease in weight and drag, since the majority of an airplanes flight time is spent at cruise conditions.